Screen printing t-shirts is known as a present day and simple method of boosting the look of your t-shirt and various garments by applying ink through custom made screens. This particular printing style allows you to transfer complicated graphics on to the t-shirt and with the state-of-the-art systems readily available you will get images and text in several colors and in just about any design or pattern you want. Additionally, the designs printed on your garments are long lasting, and if have them printed by a professional, you can be comfortable knowing that they’ll last for the lifetime of the t-shirt.

Who is one of the best screen printing provider around? Well Fast T-Shirts has something to say about that. Contrary to some other popular printing methods, silk screening printing requires a lot of expertise and experience to get it correct. Here is a small behind the scenes on how the actual screen printing practice works on t-shirts.

How to Transfer Artwork to the Screens

The very first thing is always to think of the artwork or saying that you’d like to have printed on the t-shirt. You could have just about anything from a very simple word or phrase to some colourful and complex design, nonetheless it is very important to understand that complex and more colorful graphics are more costly to have printed. When you have the image on paper, it’s going to be required to get it onto a transparancy so that it can be transfered on to a screen. This could be done by drawing the design directly on to a transparancy, or typically, digitized right into a computer first, and then printed on a transparancy. After the transparency is produced, the next phase is to transfer it to a screen. This can be completed by placing the transparency of the artwork on to a screen and then exposing the screen to a light source, normally using a specialized light table to burn the design into the screen. When the graphic is transferred, the screen is rinsed leaving behind the region where the design use to be, now available to pass ink through.

Testing Your Print

Even though the work is by an expert, it can be hard to really know what the artwork looks like on a t-shirt without doing a true test print. For this reason, it’s very important to perform some test prints by printing the design on a test t-shirt. Occasionally it’s also important to do the tests on material with the exact same attributes as the actual t-shirt to get a precise image of how the artwork will appear.

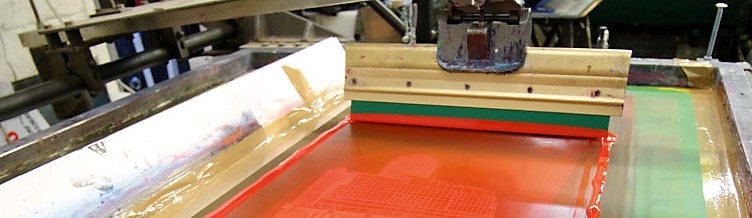

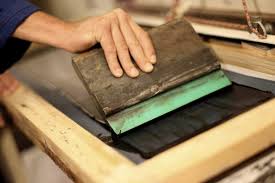

Time to Print Your Design On Your T-shirt

Transfering the design to the t-shirt usually fairly easy, however it really depends on the kind of ink you are using as well as the t-shirt it’s being put on. Prior to applying ink, it is important to ensure the artwork is lined up on the t-shirt so that the design will be in the correct location when applying ink.

Cure Your Image

Adequately curing the image is an essential step that results in many novice screen printers with poor results. A conveyor dryer offers the best and effective way to do this, and it’s exactly what a reliable guru like Fast T-Shirts uses when working with so many t-shirts.

Clean-Up the T-shirt

Soon after curing, the t-shirt will require a couple of minutes to cool-down after which it’ll be safe to launder. Modern screen print inks don’t require any special washing techniques, therefore cleaning is an easy process. Nevertheless, the t-shirts still require the same care that you give your other t-shirts.

Customized t-shirts are an outstanding marketing strategy for your organization, and are also an effective way for an individual to get the appearance they want and not settle for whatever they come across in stores. Nonetheless, to make certain the print work that you receive is high quality, you should use an expert. And when you are in the need of custom made screen printed t-shirts, Fast T-Shirts is simply a telephone call away.